Drilling Wing Spars

Drilling the wing spars proved to be a bit more than just getting out the drill or setting up the drill press. First of all, at 17′ long I could not use the drill press at all. The holes were critical to the attachment of the wing so every hole needed to be perfectly lined up with the steel fitting and they needed to be 90 degrees to the face so the bolts would go through both sides with out any binding. I decided to use a very typical drilling method so I made a drilling jig to drill the holes. The pictures will detail the process. First step was to locate the fitting on the spar according to the drawings. Next, I made the drilling jig from a 2″ thick piece of Walnut from my carving wood. I was working on the 5/16″ holes first so I needed a piece of 5/16″ tube for a sleeve to align the block to the jig and to center the first drill. I turned a piece of 3/8″ .065 tube down to the correct size using my belt sander. A lathe would have been much easier but I did not have access to one. I drilled a hole .308″ in the block an pressed the sleeve in place with the top flush and the bottom sticking out enough to go into the .090″ thick attach fittings. The sleeve would align the block and provide a guide for drilling. I first drilled out the tube to .248″ for the pilot hole. The block had a second hole reamed out to .312″ for the bolt hole. I was going to use a reamer for the .312″ hole as it gives a better finish than a drill bit. Now for some pictures:

With

the fitting in its proper place on the spar, the block is set onto the hole

with the sleeve providing the alignment for the pilot hole.

With

the fitting in its proper place on the spar, the block is set onto the hole

with the sleeve providing the alignment for the pilot hole.

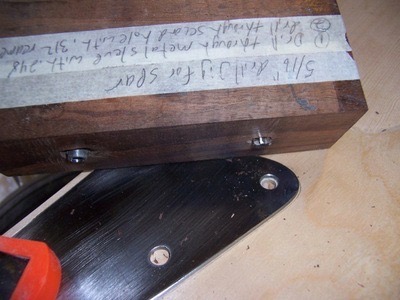

The

block is clamped in place. I used a couple more clamps to hold the

fitting in place.

The

block is clamped in place. I used a couple more clamps to hold the

fitting in place.

The first hole is drilled with .248″ piloted drill bit.

The first hole is drilled with .248″ piloted drill bit.

You

can see how nicely this set up drills the first hole. The jig is then

positioned with the .312″ reamer in the second hole in the block and centered onto

the fitting. This reamer is used to drill the hole to size.

You

can see how nicely this set up drills the first hole. The jig is then

positioned with the .312″ reamer in the second hole in the block and centered onto

the fitting. This reamer is used to drill the hole to size.

Above is the reamer being used to align

the block for the final hole.

Above is the reamer being used to align

the block for the final hole.

This

is the reamer being used on the second hole in the fitting. After I

reamed the first hole, I placed a bolt in the hole and repositioned the jig

block for the second hole. The same process of align, drill, align with

reamer, and ream hole is repeated for each hole.

This

is the reamer being used on the second hole in the fitting. After I

reamed the first hole, I placed a bolt in the hole and repositioned the jig

block for the second hole. The same process of align, drill, align with

reamer, and ream hole is repeated for each hole.

With

the 5/16″ holes done, I took a second block of Walnut and drilled a

.250″ hole; first with the .248″ drill than used a .250″

reamer. I then used a .249 reamer to locate the block over the 1/4″

hole. I used a smaller reamer for alignment so it would slid through the

wood block easier.

With

the 5/16″ holes done, I took a second block of Walnut and drilled a

.250″ hole; first with the .248″ drill than used a .250″

reamer. I then used a .249 reamer to locate the block over the 1/4″

hole. I used a smaller reamer for alignment so it would slid through the

wood block easier.

After

clamping in place, I drilled the hole with the .248″

piloted drill bit. With all the drilling and reaming, I am going through

both pieces of steel on top and bottom of the spar. After drilling I then

run the .250″ reamer through the block and into the spar for final sizing

of the hole.

After

clamping in place, I drilled the hole with the .248″

piloted drill bit. With all the drilling and reaming, I am going through

both pieces of steel on top and bottom of the spar. After drilling I then

run the .250″ reamer through the block and into the spar for final sizing

of the hole.

Perfect

fit! All bolts fit the holes exactly. Last step is to remove

the fitting and ream the holes in the spar up to .316″ so

that when I epoxy varnish the inside of the bolt holes the bolts will still fit

through. The AN 4 bolts for the 1/4″ hole are small enough that I think

they will fit after the varnish. If not, I can ream larger and

varnish. DO NOT do the final reaming with the fitting in place as you

don’t want the hole in the steel to be larger than necessary. I will

repeat this process for each fitting. Note that the fitting I use for the

drilling needs to stay with that spar incase there are any irregularities from

one fitting to the other. My plan is to completely build up the wing and

fit onto the fuselage before drilling the attach fittings for the rear

spar. That way, I can jig the wing in place and get the angle of

incidence correct before final drilling of the attach holes. I was given

this tip from another builder and it makes sense to do final rear spar drilling

after the wings are hung on the fuselage for a test fitting. This

drilling method will be used for all holes needed on the spar. Next up

after a few more holes will be fitting the ribs in place.

Perfect

fit! All bolts fit the holes exactly. Last step is to remove

the fitting and ream the holes in the spar up to .316″ so

that when I epoxy varnish the inside of the bolt holes the bolts will still fit

through. The AN 4 bolts for the 1/4″ hole are small enough that I think

they will fit after the varnish. If not, I can ream larger and

varnish. DO NOT do the final reaming with the fitting in place as you

don’t want the hole in the steel to be larger than necessary. I will

repeat this process for each fitting. Note that the fitting I use for the

drilling needs to stay with that spar incase there are any irregularities from

one fitting to the other. My plan is to completely build up the wing and

fit onto the fuselage before drilling the attach fittings for the rear

spar. That way, I can jig the wing in place and get the angle of

incidence correct before final drilling of the attach holes. I was given

this tip from another builder and it makes sense to do final rear spar drilling

after the wings are hung on the fuselage for a test fitting. This

drilling method will be used for all holes needed on the spar. Next up

after a few more holes will be fitting the ribs in place.

Note: I decided tonight (12/21/09) to drill the rear spar attach fitting holes in the spar. I first checked the fuselage fittings and found the fittings to be within .3 degrees of each other so I felt ok going ahead with the drilling. Regarding the tip to tail length, I will make all measurements from the spar attach fitting bolt hole so I should be ok here. Time will tell if this is a good decision. If things were way off than I would need to make a new spar attach fitting to compensate for any gross irregularities.