Most Recent work after long break was to build the aluminum tank covers. I tried to purchase the hat sections but was unable. Last summer, I bought a 3 in 1 shear, press, break from Harbor Freight. A god tool but it took a lot of work to get it in working order. Biggest issue is the press is too sharp for aircraft aluminum. Using a bent piece of aluminum between the press and the aluminum allowed adjustment of the bend radius to an acceptable angle.

I bent the hat sections with the brake. I made extra pieces incase I screw up one or two.

Next, I bent a curve over a wood block.

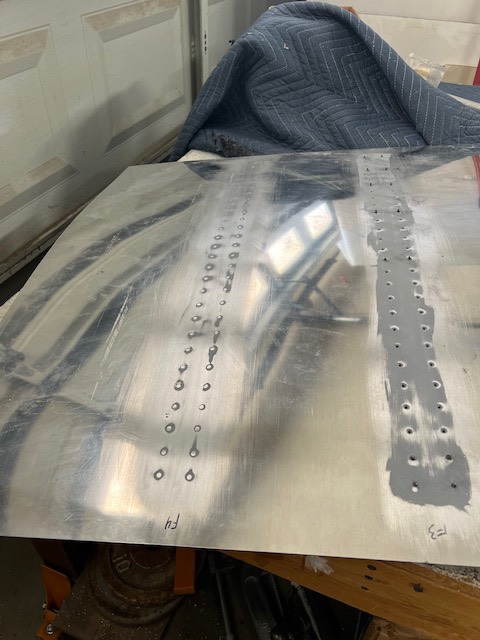

Six pieces done. I cut the covers and got everything ready to rivet. Holes were drilled in the hat sections’ one every inch. The covers were then match drilled for riveting.

Riveting was done next. I chose to back rivet the panel. It worked pretty easy. I primed before riveting.

I next used a hole finder to locate and drill the holes in the cover to match the holes in the wings.

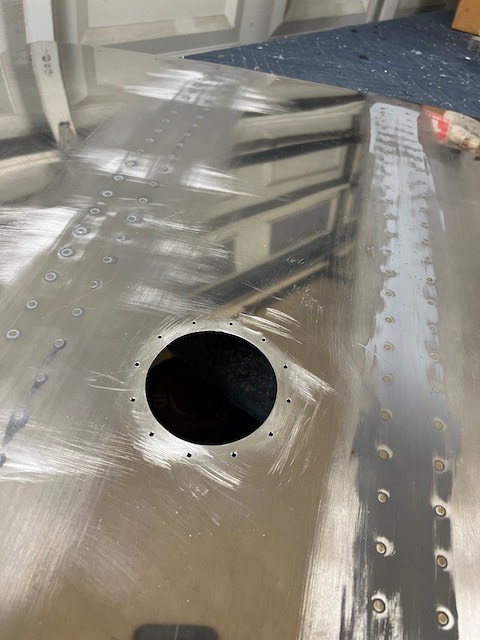

Next was to draw the hole for the tank neck and rivet on the reinforcement ring on the panel. This was easily done with the rivet squeezer. I bought the undefiled rings from Univair, nmarked and drilled the holes. I cut the opening in the cover to match my tanks, match drilled and clecoed it in place. Riveting was very easy. All rivets in the tank cover are countersunk rivets requiring dimpling both the hat section, the ring, and the cover.

Return to Past Posts and Pictures by Date