Second wing is moving along very fast! I knew that this would be the case but not to this extent. In three days I have been able get further than in the first three months on the first wing. It is a matter of having parts finished, understanding the process better, and having the tools I made for the first wing ready and at hand. These pictures will detail how much work I have been able to accomplish in the past three days. First off, I decided to get a new spar to replace the rear spar I had previously made. That spar was laminated from three pieces and would have been fine and airworthy. I wound up needing more Spruce for the flaps and ailerons so I decided to buy a new spar and use the laminated wood for the control surfaces. The extra cost was only about $50 -$75 over just buying wood for the control surfaces so well worth the cost to have all spars the same.

Here is the shop just before getting the new spar; just three days ago.

After getting the new spar, I laminated the plywood reinforcement onto the root end.

After getting the new spar, I laminated the plywood reinforcement onto the root end.

I used my drilling jig blocks to drill the holes for the wing attach fitting. After drilling the holes, I varnished where the fitting covers the wood and inside the holes.

I used my drilling jig blocks to drill the holes for the wing attach fitting. After drilling the holes, I varnished where the fitting covers the wood and inside the holes.

Next, I drilled the holes for the compression struts and the lift struts. I only drilled the front spar for the compression struts before assembly. This way I can match drill the rear spar to line up with my compression struts. I found with the first wing that my compression struts were not perfectly lined up so I need to match drill the rear spar. Below you will see I am drilling the lift strut fittings before gluing the ply on the spars. This was easier than drilling it in the upright position as on the first wing. I will have to use these holes as guides to drill through the ply but that will be easier I think.

Next, I drilled the holes for the compression struts and the lift struts. I only drilled the front spar for the compression struts before assembly. This way I can match drill the rear spar to line up with my compression struts. I found with the first wing that my compression struts were not perfectly lined up so I need to match drill the rear spar. Below you will see I am drilling the lift strut fittings before gluing the ply on the spars. This was easier than drilling it in the upright position as on the first wing. I will have to use these holes as guides to drill through the ply but that will be easier I think.

Finished drilling the lift strut, I next needed to fit ribs 3-8 and then glue the ply on one side only of the spars. The second ply will go on after drilling through the first ply.

Finished drilling the lift strut, I next needed to fit ribs 3-8 and then glue the ply on one side only of the spars. The second ply will go on after drilling through the first ply.

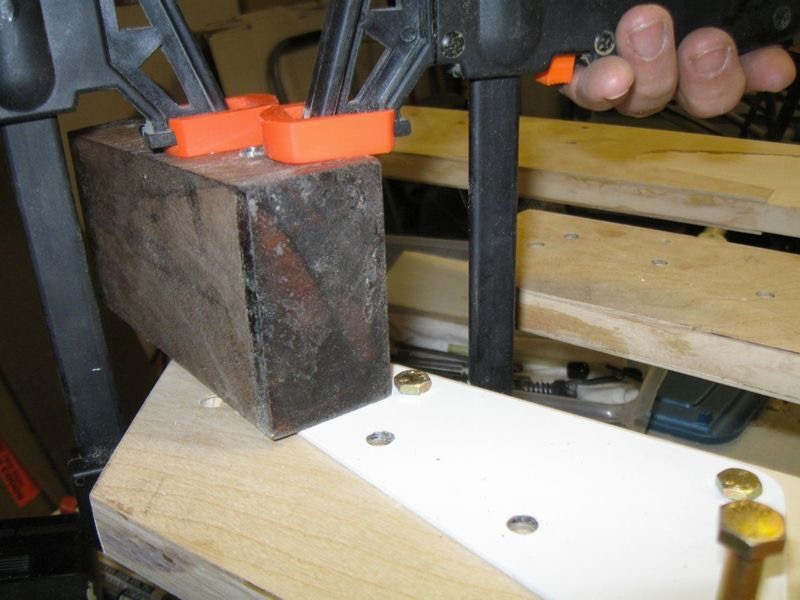

Lots of clamps are needed to secure the ply to the spars. After drying and drilling, I will glue the second ply and drill last holes for the fittings.

Lots of clamps are needed to secure the ply to the spars. After drying and drilling, I will glue the second ply and drill last holes for the fittings.

After just three days, lots of progress!

After just three days, lots of progress!