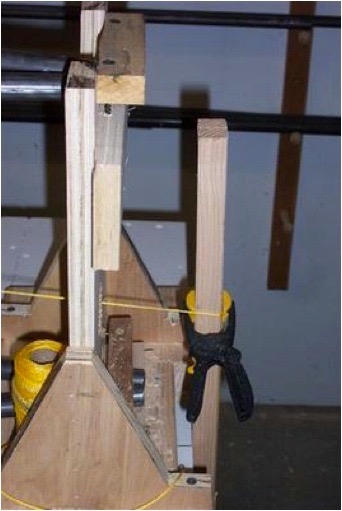

Today I finished setting the top section of the fuselage in the jig I will use to weld in the side tubes. This was the most difficult step to date! I worked on and off the past two weeks to get this just right. I followed the plans with some modifications to the jigs. I used adjustable blocks to support the tubes. The plans show notches in the jig at each tube location. I found it easier to clamp blocks in place then adjust each block up or down until the top section was level, centered, and correct front to back. When that was established, I glued each block in place then secured the top tubes in place with the blocks used to secure the tubes to the table. I had to cut holes in the jigs at most of the stations to allow the datum line to run for and aft. I also used a series of plum bobs to make sure the center line of the top section lined up with the center line of the bottom section. I then rechecked the measurements, everything seems ok. Next, fitting more tubes to make up the sides.

First placement of top section in jig.

This picture shows how I clamped the bop and bottom tubes in place. The holes in the wood are the correct top to bottom measurement. I drilled the holes first, then cut the wood down the center of the holes and then screwed them together with the tubes in the middle. Worked great.

This is the front section blocked in place with the plum bob on centerline

This is mid fuselage. The plum bob is tied off at the firewall top tube, on center and free hanging at the center of the tube shown below.

This picture is toward the rear of the fuselage. Note the hole for the datum line to pass through the bulkhead.

This last picture shows the datum line attached at the aft station where the tail post will be welded in last after all other side tubes are in place.

Return to Past Posts and Pictures by Date