There are many ways to build the windows in the doors of a 2+2. The plans show a fold out upper window. Some doors are covered in plexiglass and only have vents in the doors, and some have sliding windows. I like the idea of flying with the windows open so I chose to build sliding windows. The original PA 12’s had a wooden track for the windows to slide in. I used HDEP (cutting board material) from McMaster Carr. The window material is from Ace Hardware and I made my own edge stiffeners from .020 aluminum.

The tracks were ripped on my table saw, slide tracks done on table saw also. Holes counter sunk so windows won’t bind.

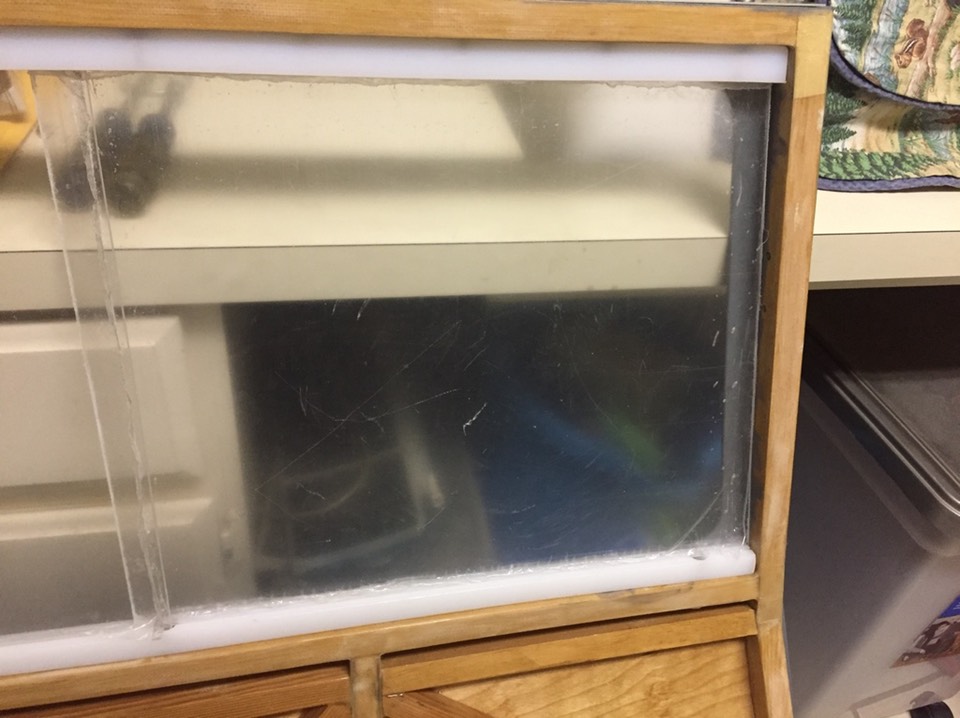

With the window tracks installed for test fit, I made patterns for the windows using the card board strip method I have previously used. Simple and effective.

Window acrylic was cut with a fine blue in my jigsaw. Make sure each side of the cut is supported very close to the cut line to avoid cracking the plastic.

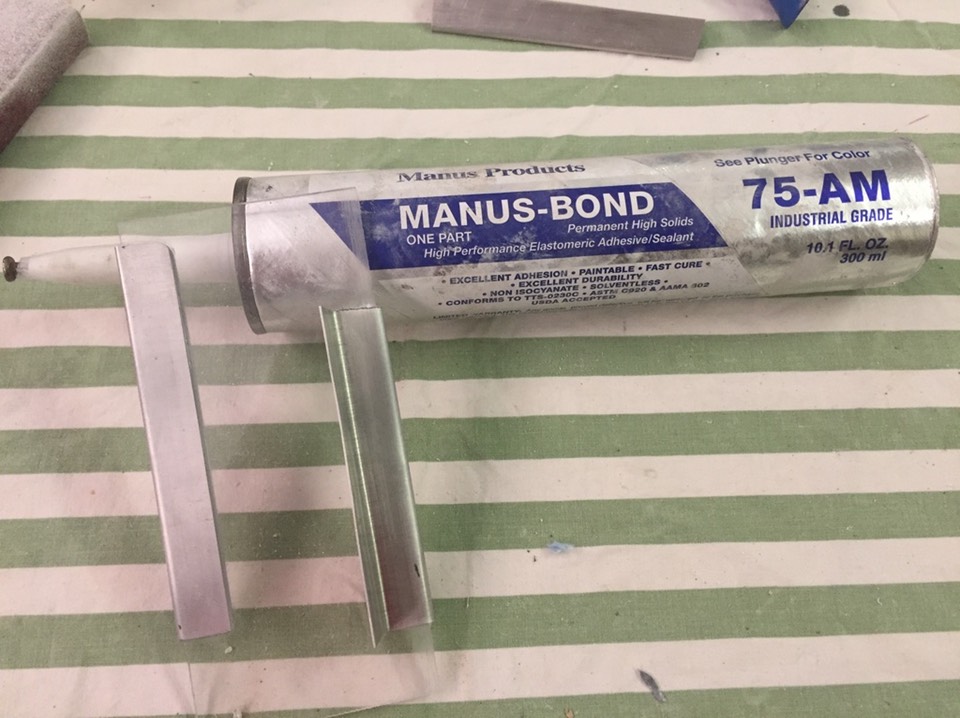

The windows were test fitted into the door and tracks. The stiffeners were just pressed into place but not glued. I’ll be using a caulking designed to glue the aluminum top to the fiberglass sides on my Winnebago motor home.

I tested the caulking on some scrap. I had just repaired my motorhome; that’s how I came up with the idea. This stuff works great. The aluminum is fully bonded to the acrylic.

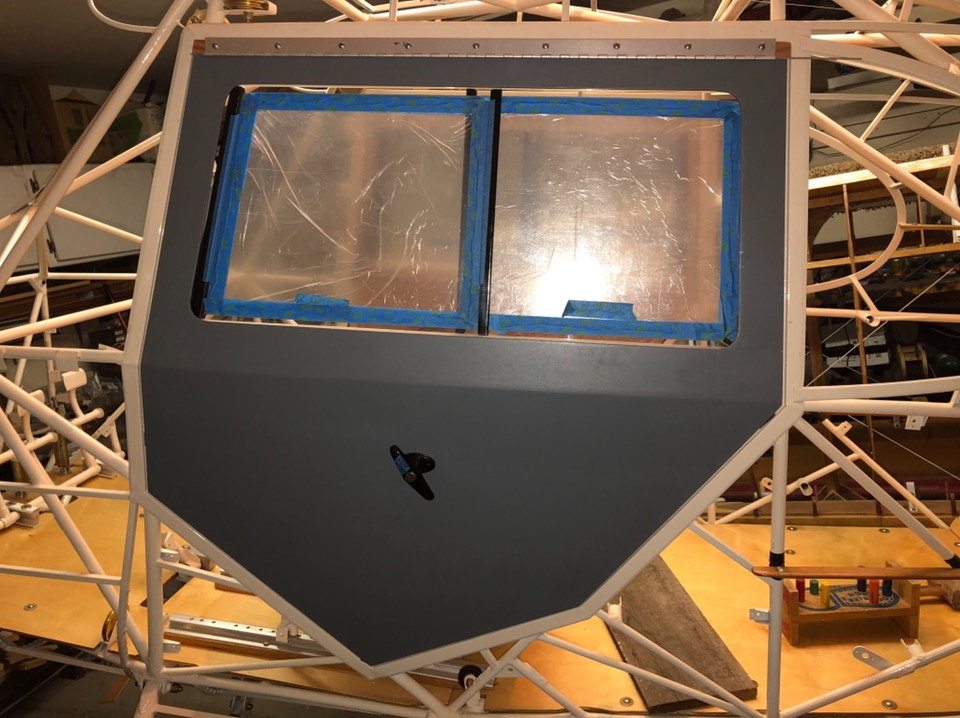

I painted the aluminum and assembled everything …… doors are done!

With the doors done, it’s time to move on to something different. I started the doors in October, 2016 and finished in June, 2017. We did take a couple trips during this time frame but these doors were still a marathon to complete. Ready to move to more assembly; the electric jack screw set up.